Polyvinyl chloride, most commonly known as PVC, is a type of plastic that garners attention for its widespread use and the resulting environmental and health considerations associated with it. Recognized for its durability, versatility, and cost-effectiveness, PVC has become a robust presence in various sectors ranging from construction to healthcare.

Its unique properties, such as resistance to moisture and chemicals, along with its ability to blend with other materials, make PVC a material of choice for numerous applications.

Although PVC’s prevalent usage signifies its utility, concerns over its impact on human health and the environment have prompted discussions on safety and sustainability. The production and disposal of PVC involve chemicals that have been linked to health risks, causing communities and regulatory agencies to assess PVC-related practices more critically.

The juxtaposition of PVC’s beneficial applications against the backdrop of potential risks positions it as a material of ongoing analysis and discussion.

Key Takeaways

- PVC is a widely used plastic with a range of applications.

- There are health and environmental concerns associated with PVC.

- Regulatory bodies are evaluating the safety of PVC use.

Overview

Polyvinyl Chloride, commonly referred to as PVC, is a prevalent synthetic plastic polymer with distinct properties that make it versatile for a range of applications. Let’s look closely at its composition and how it’s produced.

Composition and Properties

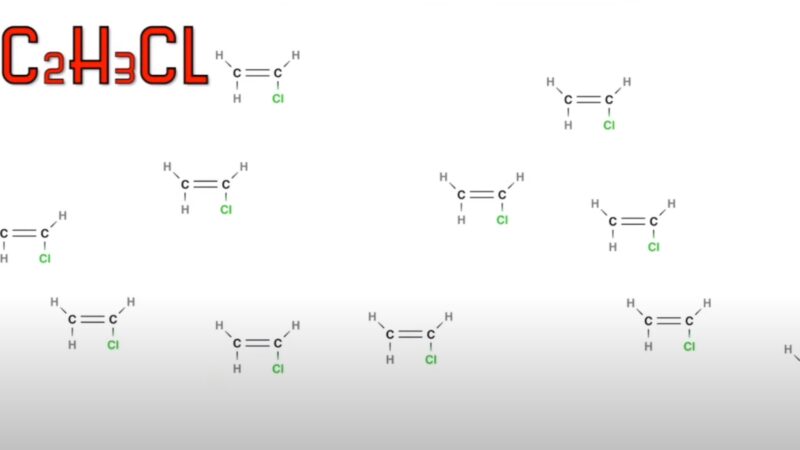

PVC is characterized by its chemical stability and durability. It consists primarily of two elements: carbon and chlorine. The molecular structure of PVC is built on repeating units of vinyl chloride, which gives PVC its rigid yet lightweight nature.

Typically, rigid PVC, or RPVC, is used in construction for pipes and doors, while flexible PVC can be found in cables, tubing, and inflatable products. PVC is also recognized for its excellent electrical insulation properties, making it suitable for various electronic applications.

Production and Manufacturing Process

The manufacturing process of PVC involves the polymerization of vinyl chloride monomer (VCM). During this process, VCM is transformed into a white, brittle solid. Starting from its raw form, PVC can be modified with the addition of plasticizers to make it more flexible, or filled with other substances to enhance its strength, color, or other properties.

The lifecycle of PVC includes some concerns pertaining to environmental and health implications, particularly during production and disposal. It is crucial to manage these stages responsibly to mitigate potential issues related to dioxin releases.

Applications of PVC

Polyvinyl chloride, commonly known as PVC, is a versatile plastic with a wide range of applications. I’ll guide you through its essential uses in various sectors.

Construction and Building Materials

PVC’s durability and resistance to environmental factors make it ideal for construction. I’ve seen it utilized in:

- Piping Systems: This includes water and sewage pipes due to PVC’s resistance to corrosion and chemicals.

- Window Frames: Owing to its low maintenance requirements and good insulation properties.

- Roofing Sheets: Their longevity and weather resistance contribute to their popularity.

Medical Devices and Packaging

In the medical field, PVC’s utility is unmatched due to its:

- Tubing and Containers: Its flexibility and safety profile lead to widespread use in blood bags and IV containers.

- Medical Packaging: Sterility can be maintained, protecting medical devices effectively.

Consumer Goods and Automotive Components

I’ve observed PVC’s presence in everyday items and vehicles. It is employed in:

- Household Items: Such as synthetic leather for furniture and shoes, due to its wear resistance.

- Car Parts: Including dashboards and seat coverings, given PVC’s ability to withstand the rigors of automotive use.

Environmental and Health Concerns

Polyvinyl chloride, commonly known as PVC, has been under scrutiny for its potential environmental and health effects. My examination of these concerns will focus specifically on the chemical’s toxicity and related health risks, as well as its environmental impact and challenges in waste management.

Chemical Toxicity and Health Risks

PVC is made from vinyl chloride, a known carcinogen and endocrine disruptor. The use of PVC in products can lead to exposure to hazardous substances, particularly during its production and disposal phases.

Studies, such as the one highlighted by the Center for Environmental Health, have raised concerns about the risks associated with vinyl chloride, including an increased risk of cancer and other health complications.

Environmental Impact and Waste Management

The production and disposal of PVC pose significant environmental challenges. Because PVC is a type of plastic, it does not break down easily and can persist in the environment for prolonged periods.

The issues of accumulation and waste management are particularly problematic, as detailed by Beyond Plastics, necessitating effective strategies to mitigate the negative impact on ecosystems and human health. Waste management practices often struggle to contain the long-term environmental risks of PVC waste, making its widespread use and disposal a contentious topic.

Regulations and Standards

In the context of polyvinyl chloride (PVC), stringent regulations and safety standards are paramount to address the environmental and health impacts associated with its production and use.

National and Global Regulatory Frameworks

My investigation into regulatory frameworks for PVC reveals that national and global institutions enforce rules to manage its production and emissions. In the United States, the Environmental Protection Agency (EPA) has set emission standards for polyvinyl chloride plants, focusing on reactor requirements and waste operations.

Globally, these frameworks vary but are aimed at controlling hazardous emissions and ensuring safe handling of chemicals.

Standards for Production and Safety

Discussing PVC production, I find that standards such as NSF/ANSI 14 and 61 control the release of vinyl chloride from PVC pipes. Furthermore, the National Emission Standards for Hazardous Air Pollutants are pivotal for workplace and environmental safety, limiting exposure to vinyl chloride—a known carcinogen.

These regulations ensure protection for both workers in the industry and the general public.

Frequently Asked Questions

Does exposure to PVC increase cancer risk?

PVC contains certain chemicals that may raise health concerns. According to the National Institute of Health, prolonged exposure to these chemicals can potentially increase cancer risk, leading to recommendations to avoid PVC when possible, especially for children.

Is PVC plastic harmful to human health?

My examination of reliable sources indicates that some compounds in PVC, like phthalates, which are used as plasticizers, may pose health risks. The debate on PVC’s safety continues, but it is generally considered safe under normal use. However, sensitive applications may require careful selection of plastic materials.

What health concerns are associated with polyvinyl chloride?

Health concerns regarding PVC mostly pertain to the release of hazardous substances during its production and disposal. Burning PVC can generate dioxins, which are harmful to human health.

Can using PVC items cause toxicity in adults or children?

The toxicity risk from using PVC items is mainly a concern if these products contain harmful additives, or when they are burned or decomposed, which can release harmful chemicals. The advice from health institutions often includes using alternative materials when possible, in order to minimize any risks, particularly for children.

Are there any significant risks associated with wearing PVC-based materials?

Wearing PVC-based materials is not commonly associated with significant risks under normal conditions. However, the production of PVC clothing can involve the use of toxic chemicals, which may present risks during manufacturing.

What are the environmental impacts of polyvinyl chloride production and disposal?

Polyvinyl chloride production and disposal carry significant environmental impacts, including the release of toxic chemicals and persistent pollution. Environmental concerns with PVC are substantial, as the material is not biodegradable, and improper disposal can lead to long-term contamination.

Conclusion

Polyvinyl chloride, commonly known as PVC, stands as a testament to the complexities of modern materials. Its widespread application across various industries, from construction to healthcare, is a clear indicator of its versatility and utility.

However, the flip side of its extensive use is the growing concern over its environmental and health impacts. The production, use, and disposal of PVC involve significant environmental considerations and potential health risks, particularly due to its chemical composition and the presence of hazardous substances like vinyl chloride and dioxins.